The lowly 8051 proves worth its weight in gold

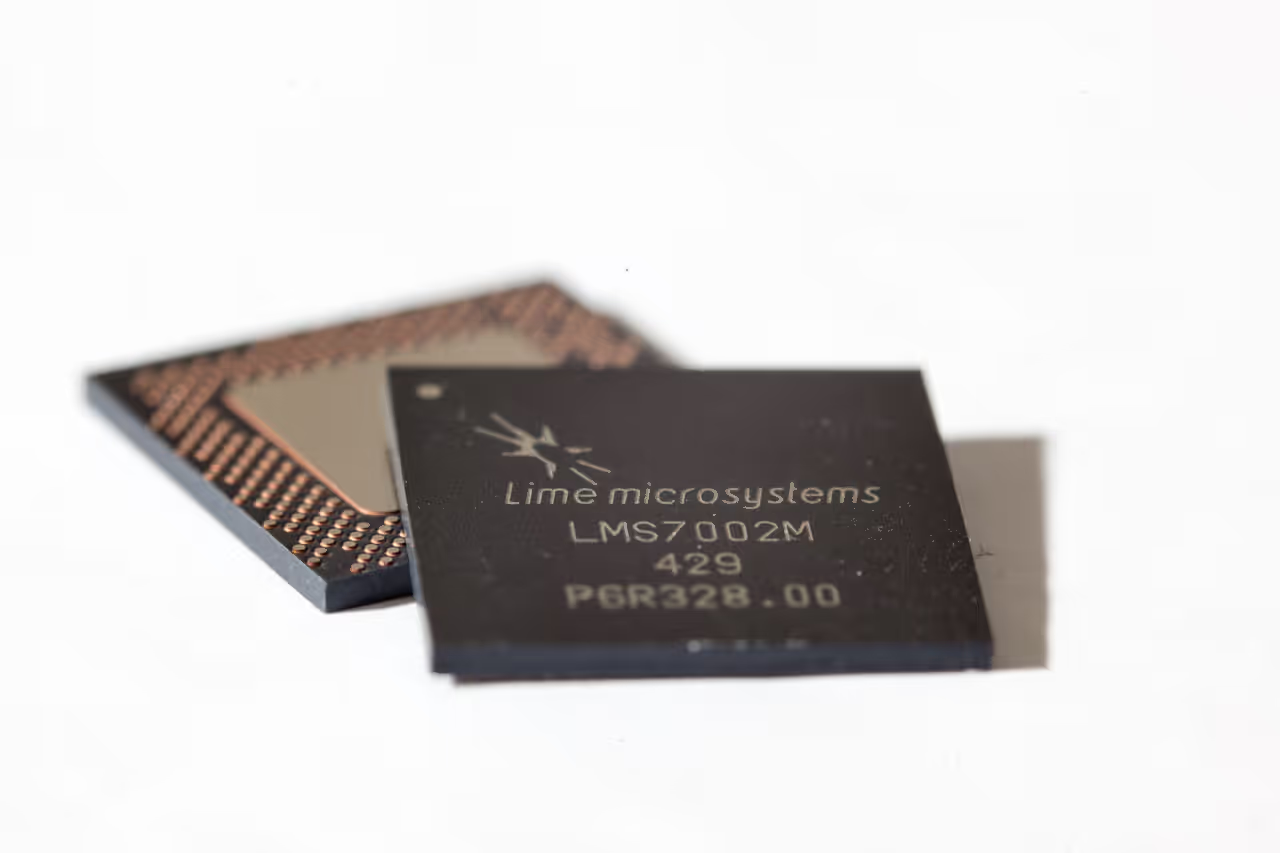

When I first read the data sheet about the new field programmable radio frequency (FPRF) LMS7002M device, I confess I took little notice of the 8051 microcontroller. I was too distracted by the dual transceivers, massive frequency range, MIMO technology, low power and DSP blocks for the microcontroller to register.

It was only when talking to the guys at Lime that I started to understand why it was such a useful addition. To lift a sentence from the data sheet: "the controlling processor needs to implement a set of calibration, tuning and control functions to get the best performance out of the transceiver". Now this control might come from the companion baseband chip, and it is easy to visualize it setting the operating parameters such as frequency, gain and bandwidth. But calibration is something that can be tricky for the baseband chip to handle. It needs a lot of interaction between the two chips, with instructions and results passing backwards and forwards. This was driven home to me when I sat in on a webinar given by Analog Devices talking about setting up the AD9361 for MIMO operation. ADI needs to loop back the RF, and reset the PLLs, but the reset does not operate on the divider chain. So there can still be a phase difference, which needs a software algorithm to resolve. This imposes additional work load on the baseband chip.

Contrast this with the LMS7002M, where the microcontroller can complete the full calibration. As I understand it, Lime has been tuning the calibration algorithms for some significant time. These algorithms will be published early in the second calendar quarter of 2015 – so watch out for a posting on this site. Customers can take these algorithms and use them to program either the on-chip 8051 or an external processor if they prefer. Lime expects to have optimized 8051 code ready for customers around a calendar quarter after the algorithms are frozen.

Automating the task of calibrating the device has the biggest impact on the production line, of course, where it saves time and money. But it is always good to know that the device you are using is well calibrated while you are using the LMS7002M in a development or experimental role.